With the economy in different stages of reopening across the nation, the use of facemasks has become a part of daily life. However, various design issues remain, including air leakage, which can render the intended use of a mask less effective, and eyeglass wearers experiencing fogged up glasses, which can lead to reduced compliance in wearing the masks. Researchers at Georgia Tech have designed a reusable, washable facemask with the goal of creating a piece that is more comfortable and effective; they will also make the specifications for the mask available to manufacturers.

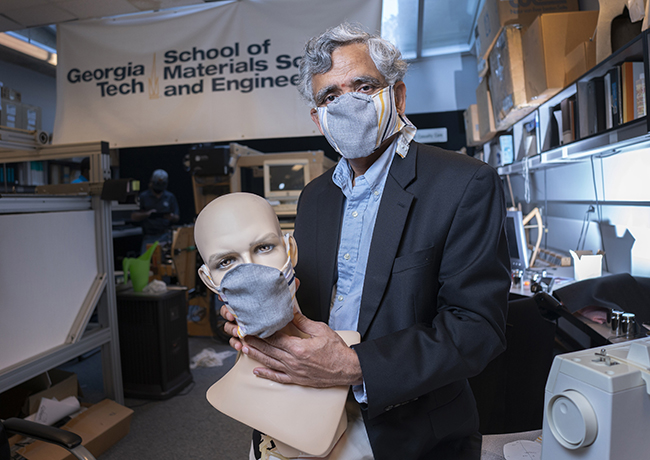

It is important to note that Sundaresan Jayaraman, the Kolon Professor in Georgia Tech’s School of Materials Science and Engineering, and Sungmee Park, principal research scientist, are well-versed in respiratory protection and the development and use of facemasks: Ten years ago the CDC funded their work to study facemasks during the outbreak of the avian flu.

“There is so much misinformation about what face masks can do and cannot do,” said Jayaraman in a Georgia Tech news release. “Being scientists and engineers, we want to put out information backed by science that can help our community reduce the harm from SARS-CoV-2.”

Key aspects of the facemask redesign include:

- Washable (the prototypes were washed at least 20 times and did not shrink or lose shape)

- Barrier filtration, moisture-wicking material with stretchable fabric

- Fabric filter made of Spandex and polyester

- Cotton was not used, as its tendency to absorb moisture can make it a breeding ground for bacterial growth

- Two-part design that fastens behind the head (similar to N95 respirators)

- Hook and eye fasteners for behind the ears to help keep the mask on

- Contoured front that encourages a tighter fit to avoid air leakage

- Pocket for optional filter, which increases protection

The work by Jayaraman and Park has been published in The Journal of the Textile Institute article, “From containment to harm reduction from SARS-CoV-2: a fabric mask for enhanced effectiveness, comfort, and compliance”.