In the United States, more than 100,000 people are waiting for organ transplants. Bioprinting tissues is seen as the future of addressing the demand for transplants and helping potentially prevent organ rejection (because the organ would be printed from a patient’s own cells). Although we are decades away from this becoming a reality, a team of bioengineers from various institutions nationwide may have brought us much closer to the possibility of 3-D printed organs.

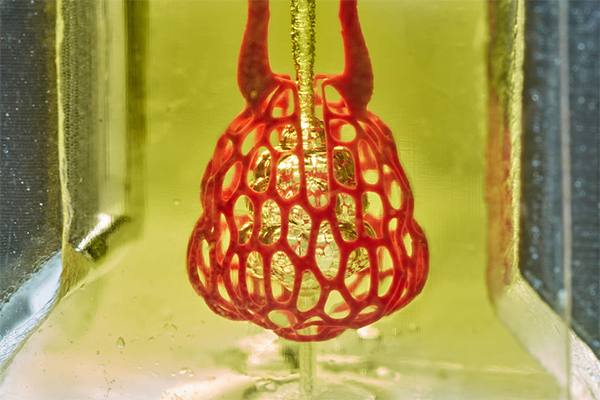

The researchers have demonstrated proof-of-principle with a hydrogel model of a lung-mimicking air sac, an entangled vascular network that could deliver oxygen to surrounding blood vessels. The work was featured in a recent issue of Science.

The inability to print complex vascular networks that can also deliver nutrients to densely populated tissues has been a significant roadblock facing the successful creation of functional tissue replacements, according to Jordan Miller, assistant professor of bioengineering at the Rice University Brown School of Engineering. “Our organs actually contain independent vascular networks—like the airways and blood vessels of the lung or the bile ducts and blood vessels in the liver,” Miller said in a university news release. “These interpenetrating networks are physically and biochemically entangled, and the architecture itself is intimately related to tissue function. Ours is the first bioprinting technology that addresses the challenge of multivascularization in a direct and comprehensive way.”

The team from Rice University, the University of Washington, Duke University, Rowan University and Nervous System (a design firm) developed an open-source bioprinting technology called SLATE (stereolithography apparatus for tissue engineering). Through additive manufacturing, layers of soft hydrogel, which become solid when exposed to blue light, are built one at a time. The researchers added food dyes that absorb blue light, which enables the creation of very fine, intricate layers in just minutes. They were able to show that the tissues were strong enough to withstand bursts of blood flow as well as the intake and outflow of air that creates pressure while breathing.

Miller’s lab is working on new design and bioprinting methods that could enable the creation of more complex structures. He predicts that bioprinting will be a “major component of medicine” within the next 20 years.