The Current State of CAPA and Beyond

What do we see after 10 years of successes and failures? Many companies are still failing regulatory inspections. As we better understand how to utilize risk and select the appropriate paths and actions, we come to see that the later stages of the CAPA process are often not well executed. The most common failure is poor effectiveness-checking to ensure that a higher degree of risk investigation and corrective response to the root cause has indeed solved the problem and eliminated the risk. The FDA is constantly writing audit findings for this flaw. While the front end of the CAPA process is improving, the back end is not.

The new emphasis in the 2016 international standard will focus more on prevention. This may cause some confusion and an over-emphasis in this area, perhaps bringing on a smaller stage of Death by CAPA for those who do not understand how to deploy or over-deploy this emphasis.

Automation of the CAPA process, when done correctly, can provide a great advantage, and likewise when done poorly can be a significant disadvantage. Many small device manufacturers would be wise to make sure that the CAPA process works on paper and that the procedures align before stepping into a rigorous automated control system. Once aligned, automation can provide many benefits, including document control, reports, management meeting tools, and alerts and alarms for adverse events and other escalations.

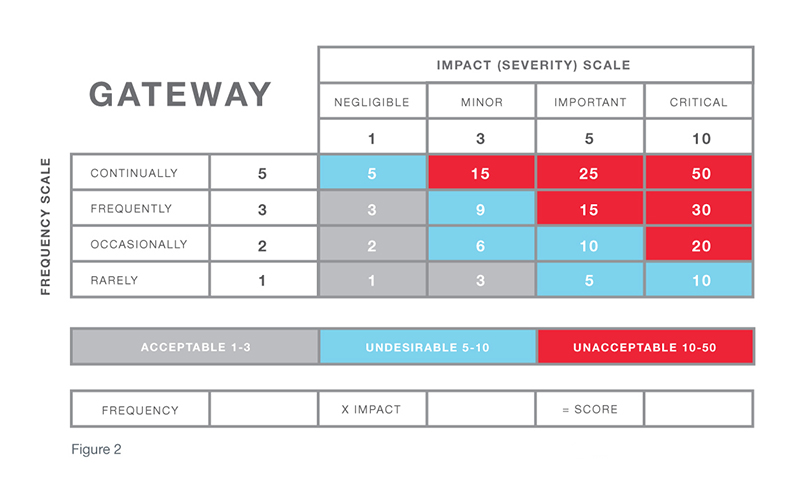

The CAPA process, otherwise referred to as deviation management, is a daily system of placing quality events or your company’s problems into a process that takes them from deviation to resolution. Placing continuous quality improvement (CQI) projects into the CAPA process is a recipe for additional problems. If you wish to move your CQI initiatives into a parallel system outside of CAPA, you must have a two-way, or binary, gate where you can only go one way or the other, similar to only being able to turn left or right when encountering a fork in the road. Misunderstanding this binary gate concept is leading to a new wave of Death by CAPA for some organizations.

Conclusion

Companies using a risk system commensurate with the new standards are seeing great advances in resource prioritization, time management, production advances, and many other facets of more productivity and effectiveness. Risk considerations are helping eliminate Death by CAPA and turning the CAPA system into a highly integrated part of the organization for managing and reporting on quality events in a broader quality event management process as part of the overall quality management system.

Moving forward, regulatory agencies will require more of manufacturers in order to demonstrate they are eliminating risky situations from all aspects of the business. Incorporation of these techniques into your systems will bring better results both now and perpetually in the years ahead.