Over-the-Counter (OTC) hearing aids are just one example of the disruptive changes underway in the world of hearables and medical remote-monitoring and fitness-tracking wearables. As of October, hearing aids are now available to buy in retail stores without a medical prescription throughout the U.S. It is expected that OTC classification will help lower the cost of hearing aids while fostering innovation and competition. As with these and other wearable devices, though, there remains a major obstacle: the microbatteries used to power them.

Until recently, the prevailing powering solution for small, connected devices has been rechargeable Lithium-ion (Li-ion) coin cell batteries that are limited in how much energy density they can deliver and locked into a single, cylindrical form factor. There will soon be another option: rechargeable solid-state lithium microbatteries that have been adapted to the specific requirements of wearables and hearables.

These microbatteries will offer higher energy density in smaller, rectangular batteries with customized lengths and widths, and they will come alongside other electronic components in a standard assembly process. These new capabilities will have a significant impact on how the next generation of medical wearables and hearables will be designed, manufactured and used.

Breaking The Battery Barrier

Hearing-assistance devices have many of the same requirements as any other wearable device, from smart fitness-tracking rings to continuous glucose monitors (CGMs). Each requirement is becoming more difficult to meet with Li-ion microbatteries.

Safety is critical—and problematic—with Li-ion microbatteries, whose liquid electrolyte can be damaged by the ambient environment. To protect against this vulnerability as well as over-voltage and over-current electrical conditions, these batteries require safety mechanisms and interior packaging that take up valuable space otherwise available for energy storage.

This storage barrier must be broken in order for wearables to monitor an increasing number and variety of inputs over longer periods of time before they need recharging. For example, today’s fitness trackers use photoplethysmography (PPG) sensors to track everything from heart rate and heart rate variability to blood pressure, VO2 max, respiration rate and lactate threshold. At the same time, these devices issue notifications, display information, and are used to take phone calls, all of which consume battery energy.

To support all of these requirements, wearables need greater energy density per unit volume, also known as volumetric energy density (VED). They also need to charge faster, support high current pulses for wireless communication, and have longer battery shelf life than Li-ion batteries, which might take just three months to lose half their charge.

Another challenge for wearable devices is that they are currently shackled to whatever standard battery size and shape is available with Li-ion technology. The easiest Li-ion battery shape to manufacture in high volumes at a reasonable cost is cylindrical, and so wearable and hearable developers have not only had to design accordingly but also include a coin cell socket that is either manually assembled or soldered onto their printed circuit boards (PCBs).

In addition, there is very little flexibility for creating wearables and hearables in the sizes and shapes that are most comfortable and effective. Developers are limited, for instance, in how much they can modify a hearable to fit better in the ear canal. Nor do they have many options for adapting a wearable’s form factor so it works best in the body location where PPG signal acquisition is most accurate.

The optimal location for PPG sensors is characterized by good blood flow, a low level of local motion, and minimal bone, muscle and other physiological features that can scatter light. Having more battery options might, for instance, steer product manufacturers toward health-monitoring headwear or hearables for certain applications, rather than devices worn on the wrist or ankle, because PPG sensors would be more effective there.

A New Type of Solid-State Lithium Battery

The industry has long believed that solid-state lithium technology would be an ideal replacement for Li-ion across a wide variety of applications. But in the 1 mAh to 100 mAh category of wearable and hearable devices, the biggest barrier to adoption has been the anode.

Every battery needs an anode, cathode and electrolyte, including solid-state lithium batteries. In simple terms, the anode is the positive electrode and the cathode is the negative electrode that receives electrons from the anode to generate electricity. The difference with current solid-state lithium microbatteries is that they use a solid—rather than liquid—electrolyte. The anode is also solid—a lithium metal layer that has typically been deposited on top of the electrolyte during manufacturing. This has delayed adoption in the wearable and hearable market because it requires a zero-humidity insert and argon (AR)-based manufacturing environment to protect the lithium from moisture and air.

No such manufacturing accommodations must be made with an anode-less solid-state lithium microbattery chemistry. Instead of depositing the anode on the electrolyte during manufacturing, it is only after the manufactured battery is first charged that the anode is created. This lithium layer is formed inside the battery, between the anode current collector and the solid-state electrolyte, as the lithium from the cathode goes through the electrolyte. There are two valuable implications.

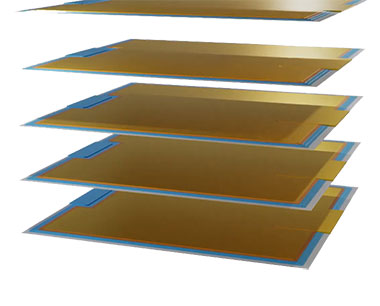

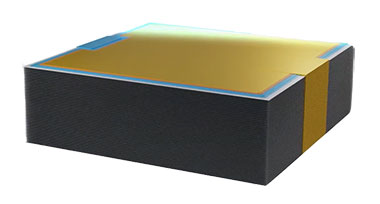

First, an anode-less chemistry extends VED to as much as double or triple that of Li-ion alternatives, and further improvements are coming. As an example, reducing the thickness of the substrate onto which battery materials are deposited creates even more room for energy storage. Stainless-steel substrates are now being used that are as little as 10 microns thick. VED can also be increased by stacking the solid-state lithium battery’s energy-producing cells on top of each other, as compactly as possible, which also increases capacity (see Figure 1a and Figure 1b). To make this possible, interfacial challenges have been solved related to the process of integrating anode-less chemistry materials while maintaining low impedance. These challenges existed between the substrate and the cathode, the cathode and solid electrolyte, and the solid electrolyte and the battery package.

The second major implication of an anode-less chemistry is it eliminates the manufacturing cost and complexity that had been deal-breakers for using solid-state lithium technology in wearable and hearable applications. Today’s easily scalable roll-to-roll manufacturing techniques can now be used to deposit the microbattery’s cathode and solid electrolyte. These techniques have already been proven in many applications besides batteries, including flexible electronics, photovoltaics, fuel cells, multi-layer capacitors, sensor materials, fabrics and paper products.

The ability to use cell-stacking and roll-to-roll manufacturing does more than just reduce cost and improve VED and manufacturing scalability. It also creates new opportunities to customize microbattery form factors and capacities. For the first time, product developers will be able to optimize their product designs for either longer battery life or expanded feature sets, or a balance of the two depending on space constraints and performance requirements. The battery’s unit cells can be cut from the roll at customized lengths and widths, and then stacked to meet capacity and height requirements. Plus, the capacity will have a longer shelf life, as solid-state lithium microbatteries have much lower leakage than Li-ion alternatives, taking four years or more to drop to half the fully charged state, compared to several months for Li-ion.

Cell-stacking also offers another benefit: encapsulating and metallizing the stacked cells enables connectors to be added on both sides. This, combined with solid-state lithium technology’s ability to withstand higher temperatures, means that microbatteries can now be directly connected to the PCB using standard Surface Mount Technology (SMT) with a low-temperature (up to +160°C) reflow profile.

Other valuable benefits of solid-state lithium technology include faster charging (up to twice that of the fastest-charging Li-ion battery) and higher cycles. It also delivers the high current pulses that are necessary for wireless communication—while Li-ion batteries can only supply up to double the rated current, solid-state lithium microbatteries deliver up to 10 times the rated current. This means that product developers will no longer need to use batteries with more capacity than required just to have high enough pulse current discharge when they need it. Solid-state lithium technology also eliminates the complex charging circuit that Li-ion batteries need to ensure reliability. All that is required is a simple, low-cost constant voltage charging solution.

Additional Indications

There is already considerable interest in rechargeable solid-state lithium microbattery technology across a broad range of current hearable and wearable applications. Under consideration are new use cases, such as powering mask devices for deep relaxation therapy that combine coordinated light pulses, sound guidance and heart rate variability monitoring. Another possibility is eyewear in a form factor that solves the sensor-to-tissue coupling challenges of using skin and PPG sensors effectively. And while wireless health monitoring devices like CGMs now use disposable primary batteries, solid-state lithium technology may become an attractive alternative, eliminating the environmental issues of having to discard batteries at least twice a month.

Solid-state lithium technology will also be an option for implantable devices including pacemakers, neurostimulators, and middle-ear hearing-assistance devices. The latter includes cochlear acoustic amplification solutions that currently using 50 mAh Li-Ion batteries, which are implanted under the skin along with the processor, transducer and microphone. Solid-state lithium technology would remove the safety issues of placing a liquid battery electrolyte in this location, while offering much higher VED and longer shelf life, among other benefits.

In the meantime, solid-state lithium technology is poised to power a wide and growing range of much more comfortable, capable and feature-rich remote health monitoring, fitness-tracking, and hearing-assistance devices, as manufacturers re-orient their design strategies to eliminate the accommodations they previously had to make for a Li-ion powering source.