Last month, theAtomoRapid™ HIV device, designed and developed by ide product development group, under contract with Atomo Diagnostics, was selected as the “Best-in-Show” winner at the 2014 Medical Design Excellence Award. The device is the world’s first integrated rapid HIV blood test, offering a simple, reliable solution for diagnosing HIV in the field and is currently being marketed in South Africa by Atomo Diagnostics.

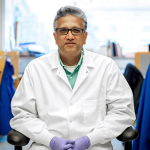

Richard Sokolov, product development director at ide, says that there is a pressure on medical device product development teams to come to terms with new types of users, environments, distribution and sales models as opposed to more traditional scenarios of device use and sale. In this interview with Medical Device Summit, Sokolov talks about the impact of current and emerging trends in this area such as consumerization of healthcare, the Affordable Care Act, use of new materials, 3D printing…

Medical Device Summit (MDS): What’s changing in the field of product design and development? What are some new trends – connected health care, miniaturization, minimally-invasive devices etc., and how are these influencing device design?

Sokolov: One of the biggest trends we are seeing is a move to doing more treatments at the point of care (POC). This is not a new trend by any means, however the “consumerization” of healthcare, the constant cost pressures, in addition to people wanting more control over their healthcare and carrying around significant computing power in their pockets, seems to be strengthening this trend. This is putting pressure on development teams to come to grips with new types of users, environments, distribution and sales models as opposed to more traditional scenarios of device use and sale.

MDS: What’s the Affordable Care Act’s impact on device design? What are designers and innovators focusing on now to ensure that they can successfully market the product, and get it reimbursed?

Sokolov: The cost of providing healthcare is coming under continual pressure, this well-accepted reality is being universally felt around the world. The main sources of these pressures differ perhaps from an ageing population in the developed world, to a lack of direct resources in the developing world.

The Affordable Healthcare Act is a response to these pressures and the focus for designers is primarily to reduce the cost to produce a device. We have never had a medical device project where this has not been one of the primary concerns. Reimbursement always plays a large role in setting targets for the cost of goods, as the reimbursement value generally guides the price a purchaser is willing to pay. However a larger and growing trend we see in our work is the focus on “total cost” of delivering a treatment. The device cost is just one portion of this, however, the design can significantly affect all other costs. Our focus is increasingly on total cost of treatment, and, understanding the needs of all stakeholders in a products lifecycle as well as the ecosystem in which a device is used and sold, helps us develop devices with a greater impact on the cost of treatment than just the device cost itself. This makes for a more compelling purchasing decision and a more commercially successful product.

MDS: What are some innovative materials that companies are working toward?

Sokolov: Some of the trends we see is to find more cost effective material options to replace those traditionally being used. In our experience, for example, we have worked with looking at cost-effective replacements for glass, maintaining its gas barrier and sterilization properties, while providing for more feature integration at a cheaper price.

MDS: What is the role of human factors in medical device design?

Sokolov: Many devices being developed are based on the development of some fantastic and incredible technologies. Without the focus on these new technologies, novel treatments would never be possible. However, at times in pursuing new technologies or continually improving existing ones, the users who must apply the treatment fall out of focus. Yet the effectiveness of the technology can be severely compromised when the users can not apply or operate the technology appropriately. This is where human factors plays a key role, which, at times, is as important as the technology itself. Additionally, we are increasingly seeing that focusing on device usability can uncover new product opportunities that are disrupting existing devices and treatment methods.

Our work on the AtomoRapid product and the Unifill syringe is a testament to this trend. The market opportunity for these products rests greatly on their utility or usability. This interestingly also drives the development of unique technologies, to enable improved usability, and hence strong market demand. A greater imperative for us in our work is human centered design, which focuses on all stakeholders in a products lifecycle and not just the user. This leads to fundamental changes and emergence of disruptive products.

MDS: What are some challenges when it comes to medical device design and development (such as speed to market, prototyping etc)? How can these be addressed?

Sokolov: Speed of development is one challenge, and I would add cost of development as the second key challenge in medical device development. This is a continual pressure on development teams and we feel this from large multinationals and small start-ups alike. The way we address these challenges is in our fundamental approach to product development. That is, we view product development as an endeavor in managing uncertainty, risk, to exploit an opportunity. When you view development this way, then you can program your activities in a way to minimize or mitigate risks very early in the project, and ensure that you are developing the right product, which minimal time-consuming and unnecessary design iterations. It also reduces the chance you will be involved in tackling unforeseen problems late in the process, when you are expected to be shipping product and not redesigning or developing new technologies. This has profound effects not just in immediate costs of the activities or in modifying expensive capital expenditures late in the project, but on lost market opportunities or, at worst, potentially catastrophic implications of product recalls, etc.

MDS: What is the potential of 3D printing when it comes to device design and development and how can this be tapped into?

Sokolov: 3D printing is well entrenched in the development process is a truly commonplace and a key tool in the tool kit of every development team and is invaluable, especially for addressing the two challenges we have just discussed. The great thing about 3D printing technology is that no matter how common it may seem, there are always new and exciting developments, such as printing tissue and organs for treatments, to printing tumors for developing cancer treatments.

However some remarkable advancements are in what may be seemingly conventional applications, such as 3D printing injection mold tools, which we see as possibly having profound effects on industry. So the potential for 3D printing is well beyond just prototyping, it goes into directly or indirectly providing treatment or manufacturing components in production. Tapping into these technologies is made easier by working with groups who understand their potential and who take creative approaches to their application.