Imagine a world in which your loved one is diagnosed with a devastating illness that can be cured with a tailored personalized treatment that is specially designed and manufactured for them. The sky is the limit when it comes to the benefits of truly personalized medicine.

For example, personalization of treatment would ensure a perfect fit between tumor and immunotherapy making cancer therapy much more effective. It would cure type-1 diabetes using autologous cells negating the lifetime need for immuno-suppressors. And it would help control Cystic Fibrosis by replacing the cells that carry the diseased CFTR receptor with re-programmed cells from the same patient that now carry the healthy variant. Technically, we are not far away from this imagination being a reality.

CAR-T Cell Therapy: A Success Story

One of the most famous and successful examples of personalized medicine is CAR-T cell therapy for the treatment of B-cell lymphoma. As part of this therapy, some of the patient’s T-cells are temporarily removed from their body. Outside the body (ex-vivo), these T-cells are genetically modified using viral vectors to carry a receptor (Chimeric Antigen Receptor) that recognizes the patient’s cancer cells. Prior to re-entry into the body, the modified T-cells are activated so that they kill the target that binds the receptor. It is truly miraculous to think that—with the help of ex-vivo genetic programming—the patient’s own cells are able to cure the body from cancerous B-cells.

What is unique about this personalized approach? Traditionally, drugs are produced using fairly standardized manufacturing processes in specialized centralized facilities. However, in the case of CAR-T cell therapy, an entire decentralized infrastructure for manufacturing personalized cell therapy was re-invented to allow patients all over the world access to ground-breaking treatment. Results so far have been spectacular and many patients previously given just years or even months to live, are now cured with the help of personalized CAR-T cell therapy.

Personalized medicine: Looking beyond Cell Therapies

The success of CAR-T cell therapy paves the way for numerous other personalized treatments. Technologies like CRISPR, can now more accurately control the genetic programming of cells. In many ways, we have just scratched the surface of what is possible. Personalized cell therapies are bound to further revolutionize the world of medicine. Even more encouraging is the advancement of microfluidic technologies and AI bringing sophisticated high-throughput screening approaches for antibody and protein selection into the realm of possibilities.

For example, the microfluidic platform technology developed by Abcellera screened a complex sample containing millions of antibody-producing cells to select a specific antibody that was successfully developed into a drug for the treatment of COVID-19. Most exciting is that the entire process only took three months instead of the previous 15–25 years to complete.

Another recent initiative and success story is 64xBio, synthetic biology company that just landed a $55 million series-A financing round. 64x Bio is building a platform which radically increases the speed and scale of mammalian cell line discovery for the manufacturing of viral vectors. These vectors are used for cell therapies (e.g., the genetic modification in CAR-T therapy is accomplished using viral vectors) and gene therapies. Looking at these developments, it is not unreasonable to believe that in the near future, personalized medicine will extend beyond cell therapies into viruses, antibody and protein therapies.

|

|

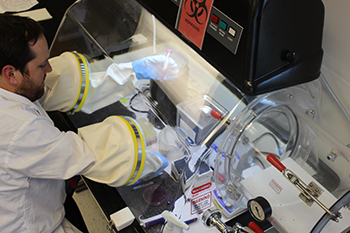

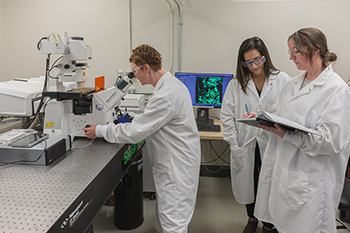

| Nick Allan (StarFish Medical) manipulates pilot batches of biomanufactured materials in an anaerobic environment. | Sandy Reid (StarFish Medical) uses confocal laser microscopy to visualize results of a biomanufacturing experiment |

| Images courtesy of StarFish Medical. | |

Challenges

The future of personalized medicine is exciting, but it also poses real challenges. Never before have we re-invented the way we manufacture and administer drugs/treatments on such a scale. Each and every personalized treatment comes with its own set of manufacturing challenges. These include growing relatively low numbers of patient-specific cells, controlling sterility in makeshift Grade-D (relatively dirty compared to a traditional Grade B clean room) hospital manufacturing rooms, integrating quality control testing of the drug product for rapid drug release, and controlling the enormous costs associated with personalized manufacturing procedures.

The weight of these challenges are currently carried on the shoulders of process engineers who are using a defined and limited toolbox of manufacturing equipment and single-use consumables. Given the requirements of personalized manufacturing processes, limitations in the existing toolbox prevent some of these novel therapies to progress to the clinic. Furthermore, the manufacturing tools that do exist in the personalized cell therapy space are dominated by a couple of large companies with very few new players. This market can absolutely benefit from many more innovate solutions and healthy competition. More collaborative initiatives need to take place between drug manufacturers and developers of manufacturing equipment and consumables.

Given the explosion of new personalized approaches and the need for new and affordable innovative manufacturing tooling and equipment, I expect a serious shortage of equipment and consumables for manufacturing of personalized treatments in the near term.

Amazing new personalized treatments coming from innovative drug development programs deserve to make it to patients around the world. Drug manufacturing process engineers should not consider themselves limited by existing tooling and equipment. If it does not yet exist, think bigger, reach out to product developers and create a better closed-system bio-reactor for adherent cells, or a novel small-scale downstream processing solution for drug purification, or a custom valve for aseptic sampling, or any other new innovative equipment deserving of the same celebration as the successes of personalized CAR-T cell therapy.